The production process of outdoor fitness equipment starts with design and planning, where concepts are developed, and engineering drawings are created to ensure functionality, safety, and compliance with international standards. High-quality materials, such as steel and weather-resistant plastics, are selected for durability and long-term use. Components are precisely shaped using advanced cutting techniques like laser cutting and CNC machining, followed by bending, rolling, and welding to assemble the primary structure.

The equipment undergoes surface treatments, including sandblasting, galvanization, and powder coating, to enhance corrosion resistance and provide a smooth, durable finish. Rigorous quality control measures, such as load testing and structural inspections, ensure the equipment meets safety and performance criteria.

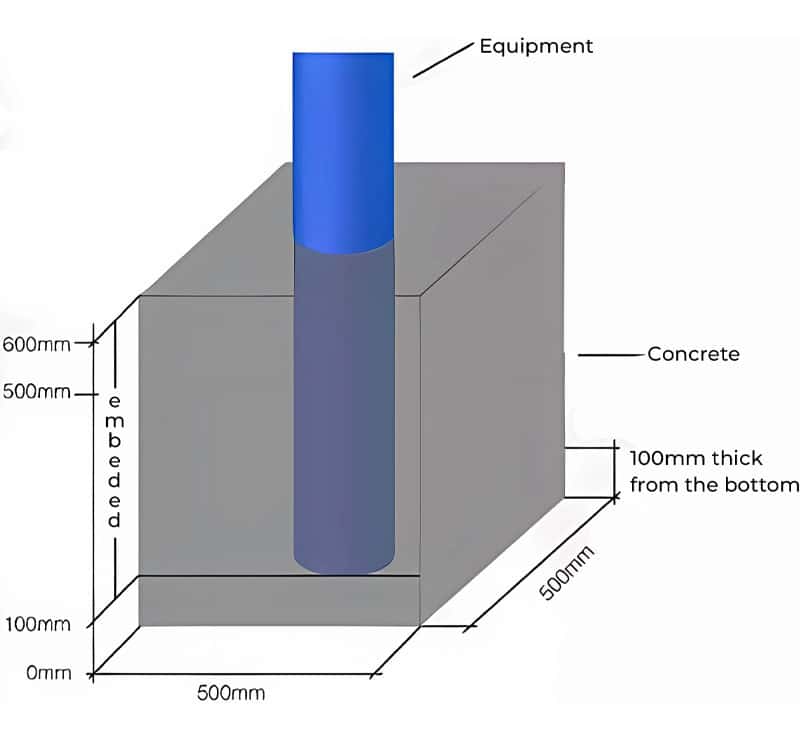

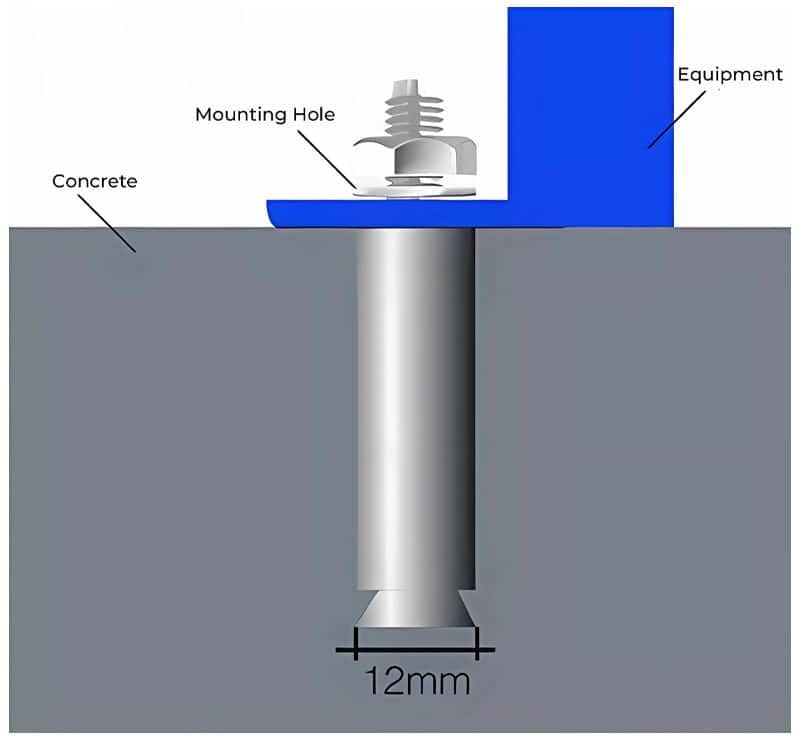

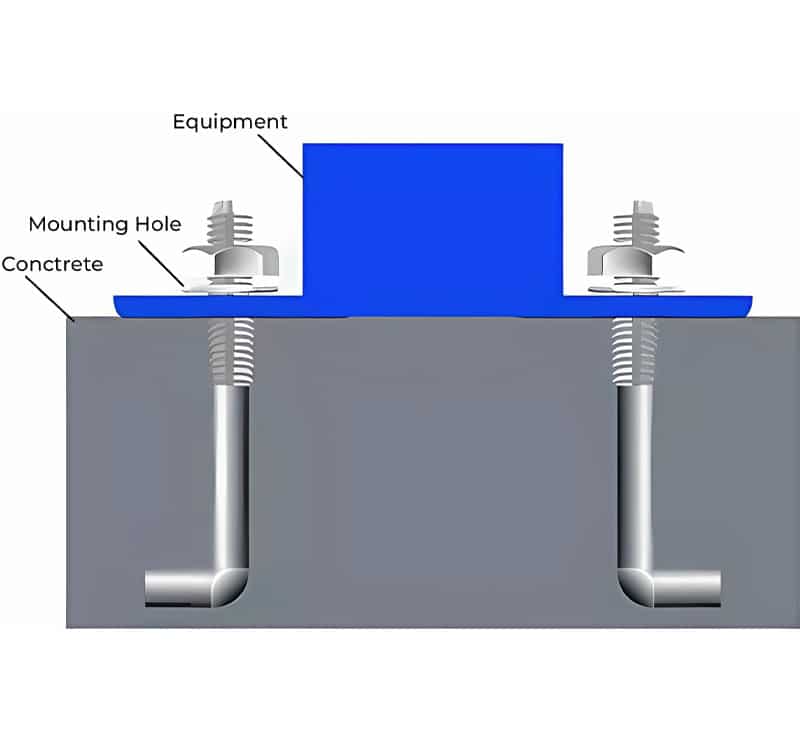

After passing inspections, components are fully assembled with fasteners and functional parts like handles, bearings, and seats. The finished equipment is then packaged securely to prevent damage during transit. Once delivered, installation teams prepare the site, anchor the equipment securely, and conduct a final inspection to ensure proper setup. This meticulous process ensures that outdoor fitness equipment is durable, safe, and ready for long-term use in diverse

Galvanized Steel Pipes

Main pipes of ∅114*2mm and other auxiliary pipes with baked paint are produced through a series of processes, including sandblasting, electrostatic powder spraying to evenly apply plastic powder onto the metal pieces, followed by high-temperature baking and cooling.

Cutting

The pipe-cutting process uses precise methods to achieve accurate lengths and clean edges. Pipes are then deburred to remove sharp edges, ensuring safety and smooth assembly. This step ensures high-quality, durable components for the final product.

Bending

The pipe-bending process shapes steel pipes into precise curves using techniques like hydraulic or mandrel bending. This ensures smooth, accurate bends without compromising the pipe's strength or structural integrity, enabling seamless assembly and durability.

Galvanized Steel Pipes

Main pipes of ∅114*2mm and other auxiliary pipes with baked paint are produced through a series of processes, including sandblasting, electrostatic powder spraying to evenly apply plastic powder onto the metal pieces, followed by high-temperature baking and cooling.

Cutting

This process uses precise methods to achieve accurate lengths and clean edges. Pipes are then deburred to remove sharp edges, ensuring safety and smooth assembly. This step ensures high-quality, durable components for the final product.

Bending

The pipe-bending process shapes steel pipes into precise curves using techniques like hydraulic or mandrel bending. This ensures smooth, accurate bends without compromising the pipe's strength or structural integrity, enabling seamless assembly and durability.

Welding

This process involves joining steel pipes through methods that ensure strong, secure bonds. Proper alignment and controlled heat application create durable welds, maintaining the structural integrity and safety of the equipment.

Welding

The pipe-welding process involves joining steel pipes through methods that ensure strong, secure bonds. Proper alignment and controlled heat application create durable welds, maintaining the structural integrity and safety of the equipment for long-term outdoor use.

Sandblasting

Sand blasting is also known as abrasive blasting, which is a generic term for the process of smoothing, shaping and cleaning a hard surface by forcing solid particles across that surface at high speeds. Sandblasting produces a better finish than blasting alone.

Powder Coating

This process involves applying an electrostatically charged powder to metal surfaces for even coverage. The coated parts are cured in a high-temperature oven, creating a durable, weather-resistant finish that enhances appearance and ensures long-lasting protection.

Sandblasting

Sand blasting is also known as abrasive blasting, which is a generic term for the process of smoothing, shaping and cleaning a hard surface by forcing solid particles across that surface at high speeds. Sandblasting produces a better finish than blasting alone.

Powder Coating

This process involves applying an electrostatically charged powder to metal surfaces for even coverage. The coated parts are cured in a high-temperature oven, creating a durable, weather-resistant finish that ensures long-lasting protection.