Playground equipment is designed to provide a safe and enjoyable play environment for children of all ages. These structures are typically made from a variety of materials, each chosen for its durability, safety, and resistance to outdoor elements.

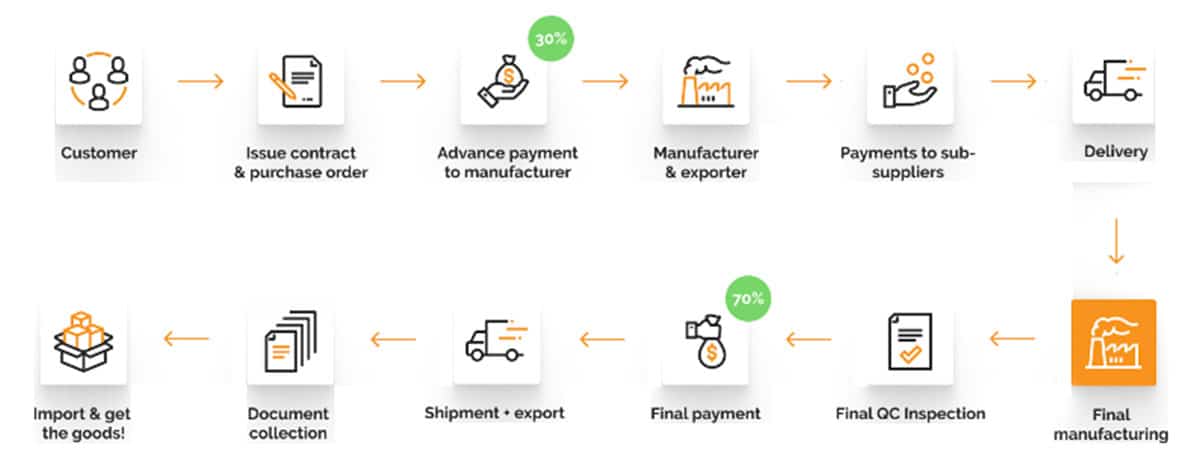

Production processes for playground equipment can vary based on the specific materials used, the complexity of the design, and the safety regulations. In general, the production process involves designing the equipment, sourcing materials, cutting, shaping, welding, assembling, and finishing (painting, powder coating, etc.). Safety standards and guidelines are closely followed to ensure that the final product meets all necessary safety requirements for children’s play.

Post/Handrail/Railing

Main posts of ∅114*2mm and other auxiliary posts with baked paint are produced through a series of processes, including sandblasting, electrostatic powder spraying to evenly apply plastic powder onto the metal pieces, followed by high-temperature baking and cooling. The result is a durable finish with strong weather resistance.

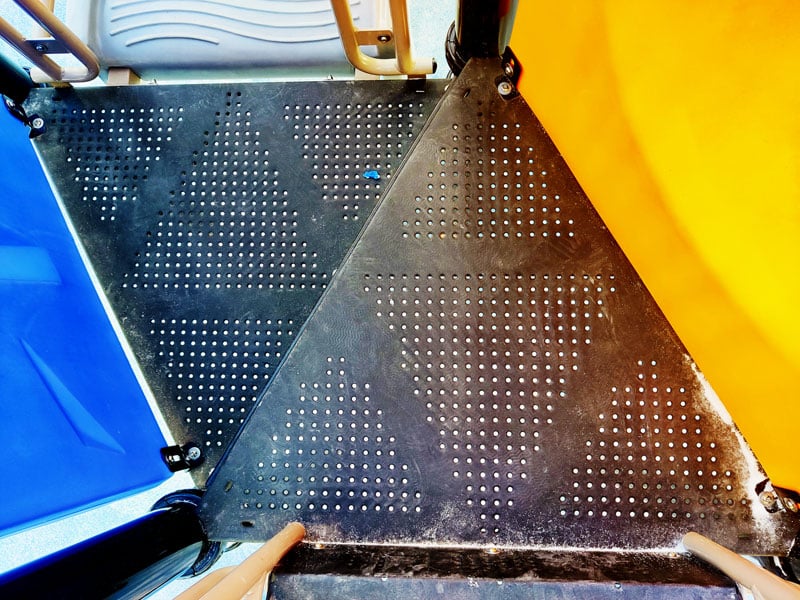

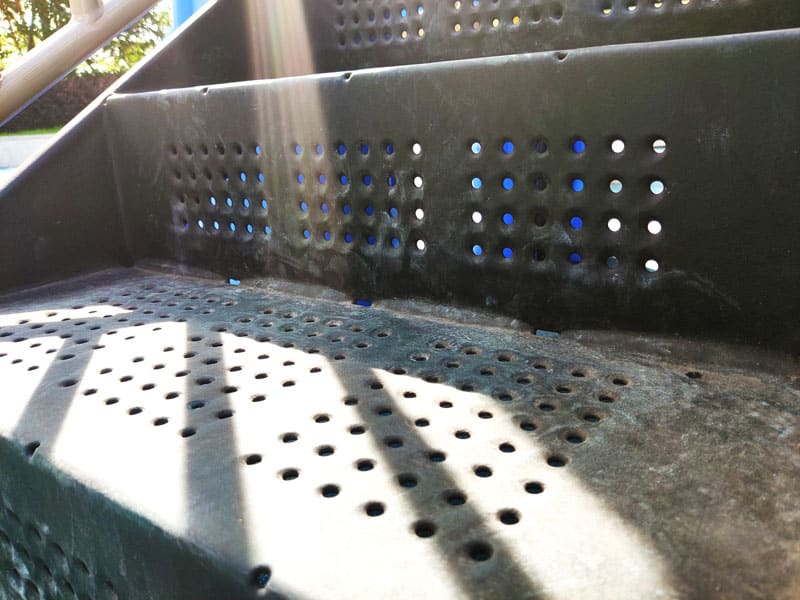

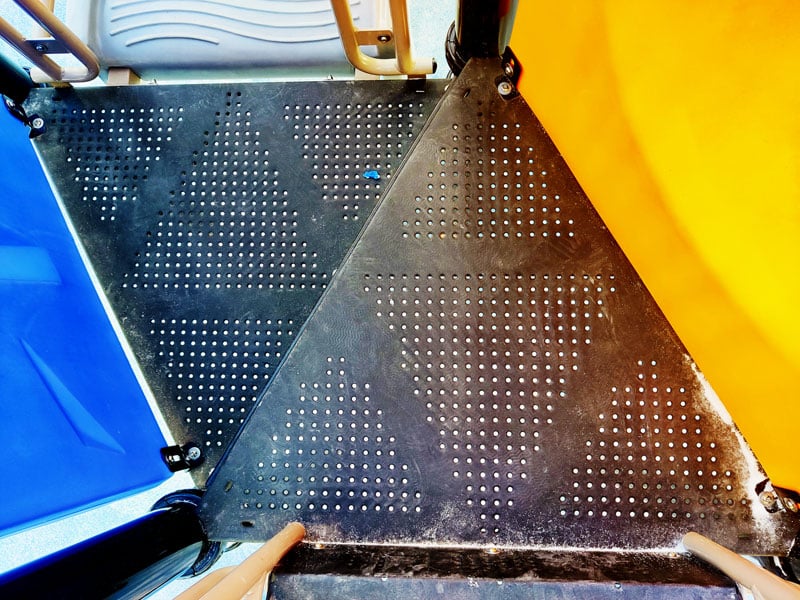

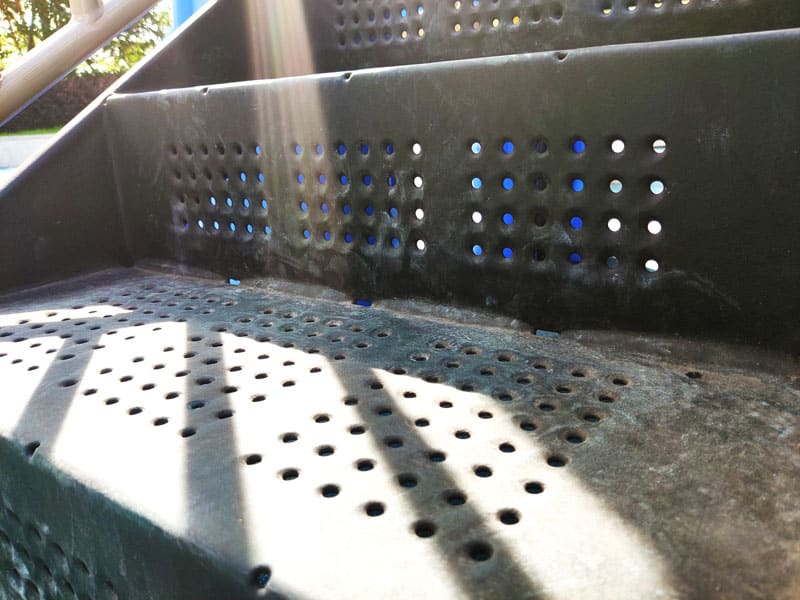

Platform/Stair

High-strength perforated plates undergo a process of rust and oil removal and then sandblasted. Subsequently, they undergo electrostatic powder coating and high-temperature curing. The entire platform can also receive a dip coating treatment, providing excellent safety and slip resistance.

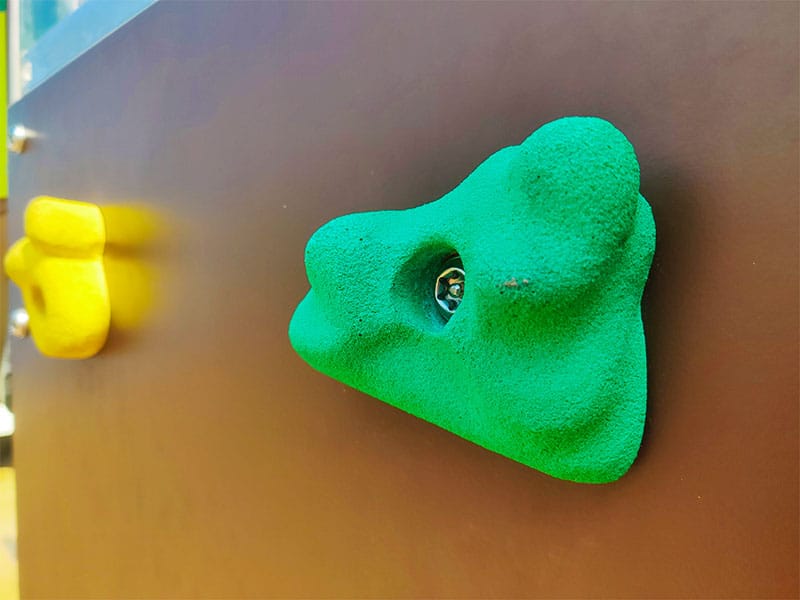

Slide/Panel/Roof

Utilizing imported LLDPE rotational molding material, processed through rotational molding, featuring bright and vibrant colors, with a finely-textured matte surface for a high-end appearance. It possesses strong UV resistance, robust anti-static capabilities, ensuring safety and environmental friendliness.

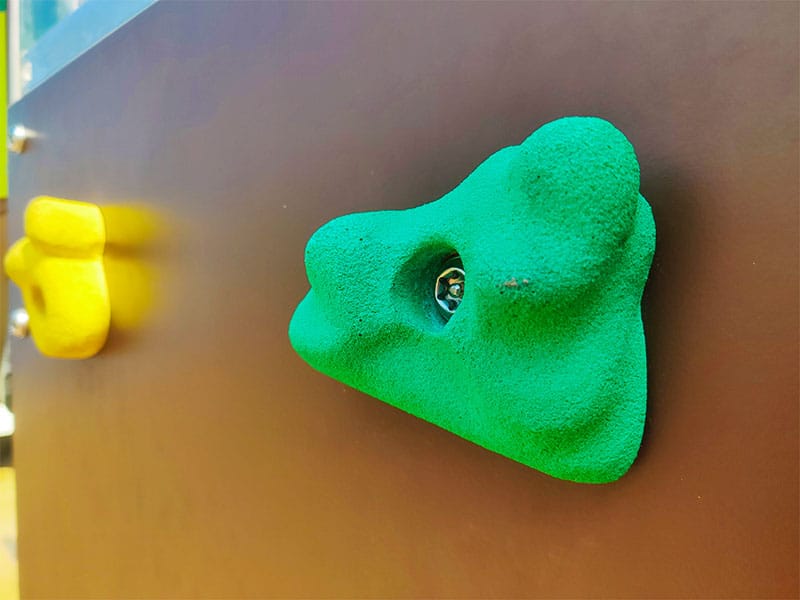

HDPE Sheet

High-Density Polyethylene (HDPE) sheets are a popular and durable material used in playgrounds due to their excellent properties and versatility. They have high impact resistance and non-toxic nature, UV and weather resistance, smooth and splinter-free surface, and they are also environmentally friendly.

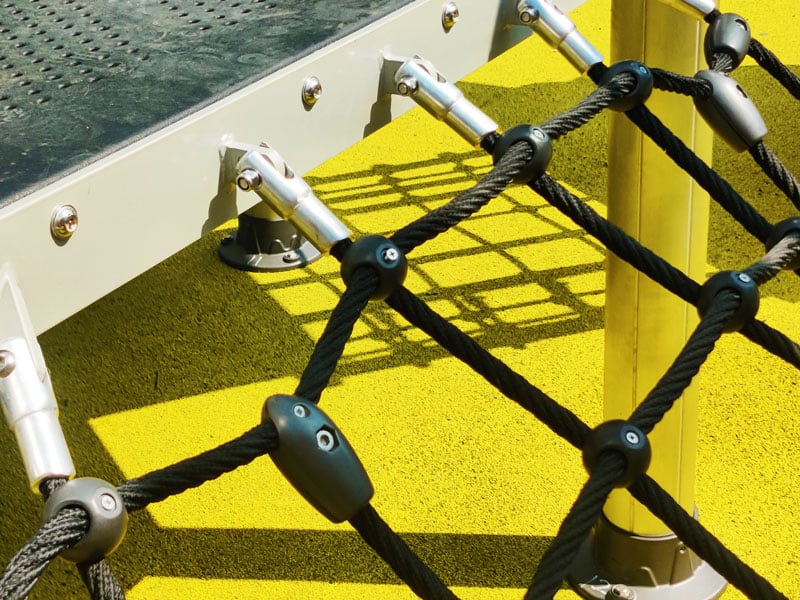

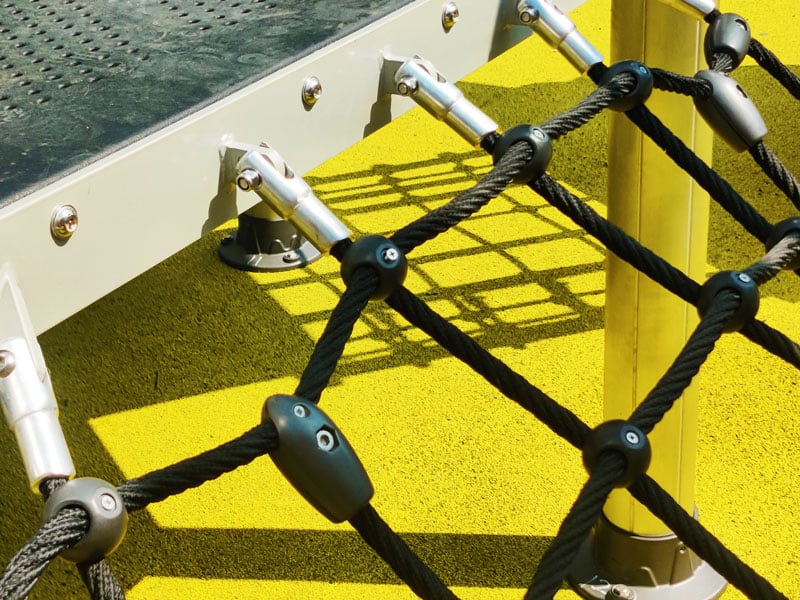

Rope Net/Tunnel

Polyester ropes are commonly used in playgrounds for various applications due to their strength, durability, and versatility. They are highly resistant to UV rays, chemicals, and abrasion. It maintains its shape well and is suitable for both indoor and outdoor playgrounds, where longevity and low maintenance are important.

Connector

Safe Connection Fastener: Made of aluminum alloy, with a round shape, high-grade appearance, aesthetically pleasing design, secure and reliable, corrosion-resistant, and long-lasting durability.

Main posts/Handrails/Railings

Main posts of ∅114*2mm and other auxiliary posts with baked paint are produced through a series of processes, including sandblasting, electrostatic powder spraying to evenly apply plastic powder onto the metal pieces, followed by high-temperature baking and cooling. The result is a durable finish with strong weather resistance.

Platforms/Steps

High-strength perforated plates undergo a process of rust and oil removal and then sandblasted. Subsequently, they undergo electrostatic powder coating and high-temperature curing. The entire platform can also receive a dip coating treatment, providing excellent safety and slip resistance.

Connectors

Safe Connection Fastener: Made of aluminum alloy, with a round shape, high-grade appearance, aesthetically pleasing design, secure and reliable, corrosion-resistant, and long-lasting durability.

Slides/Panels/Roofs

Utilizing imported LLDPE rotational molding material, processed through rotational molding, featuring bright and vibrant colors, with a finely-textured matte surface for a high-end appearance. It possesses strong UV resistance, robust anti-static capabilities, ensuring safety and environmental friendliness.

HDPE Sheets

High-Density Polyethylene (HDPE) sheets are a popular and durable material used in playgrounds due to their excellent properties and versatility. They have high impact resistance and non-toxic nature, UV and weather resistance, smooth and splinter-free surface, and they are also environmentally friendly.

Climbing Net/Net Tunnel

Polyester ropes are commonly used in playgrounds for various applications due to their strength, durability, and versatility. They are highly resistant to UV rays, chemicals, and abrasion. It maintains its shape well and is suitable for both indoor and outdoor playgrounds, where longevity and low maintenance are important.